POLISHING AND GRINDING APPLICATION

To make rough surface flat and glossy by extrusion and cutting force resulting from abrasives’ continuous rolling during machining process is the characteristic of grinding and polishing applications.By diamond powder types, the grinding tools could be divided into polycrystalline diamond grinding tools and monocrystalline diamond grinding tools.Different with monocrystalline diamond grinding tools, polycrystalline diamond grinding tools can meet customers’ high standard requirement as the very good self-sharpening ability of polycrystalline diamond powder.

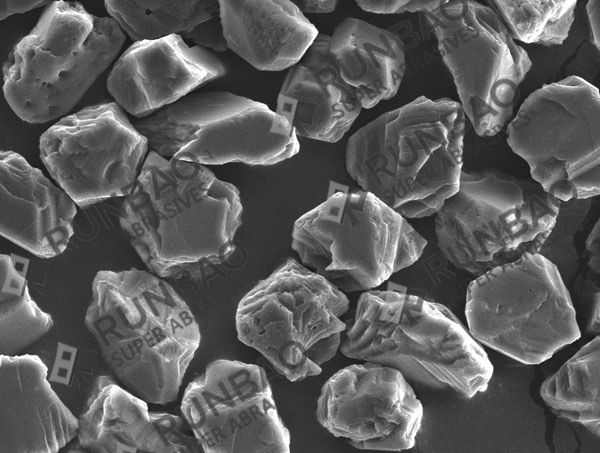

It is coming from RBV-FS. It is gray and white color. It's excellent self-sharpen characteristic brings perfect gloss

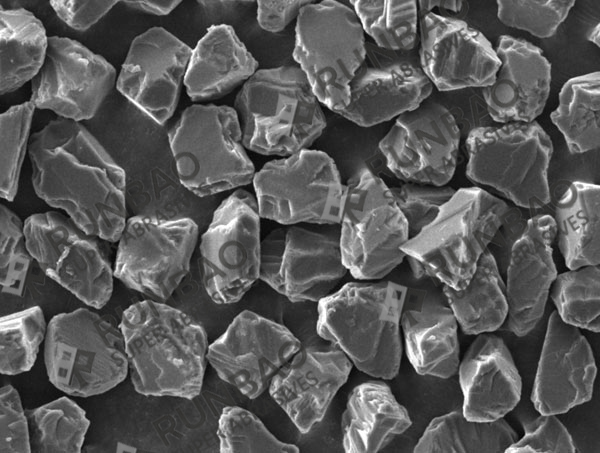

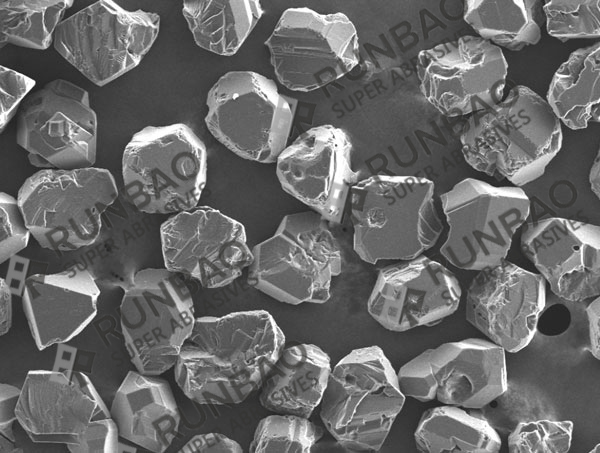

It is coming from RVD-A Higher toughness. It is light yellow and white color. With a lot sharp polishing edges.

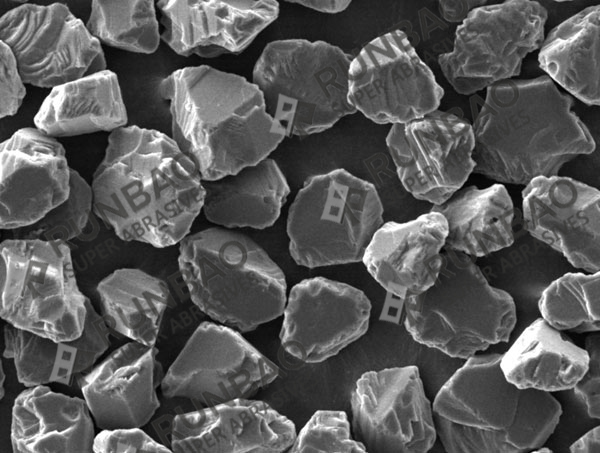

It is coming from RVD-B. Medium toughness. It is yellow green and white color, Economic grade. Very low proportion of plates.

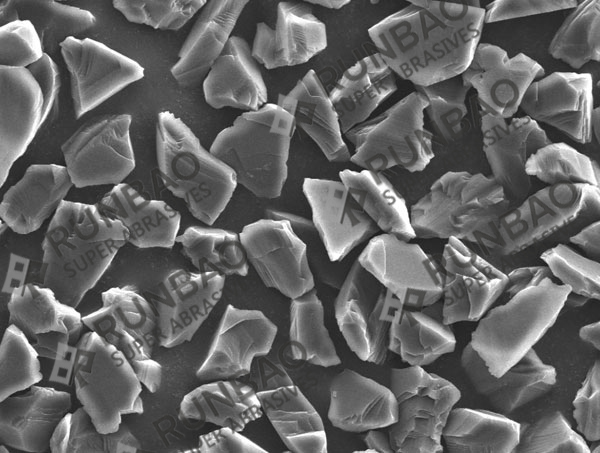

Yellow-green to white, with sharp edges, high grinding efficiency. It is widely used for cutting and throwing hard materials.