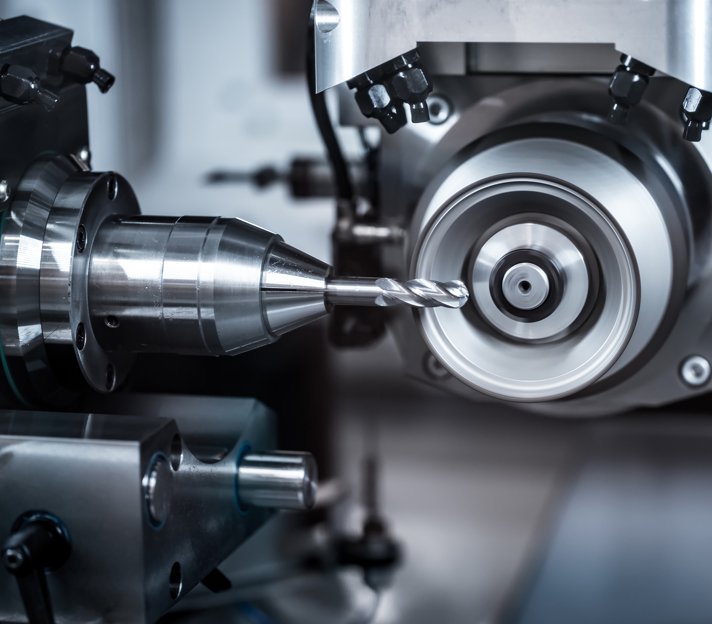

Application of grinding wheel

Its unique characteristics of diamond abrasives(high toughness, high compressive strength and good wear resistance) makes the diamond grinding wheel shows the perfect performance when grinding the hard & brittle materials and tungsten carbide.High grinding efficiency,good surface finish and longer tools’ life specially makes it widely used in grinding tungsten carbide, alumina porcelain,optical glass,agate, semiconductor, stone and other materials.

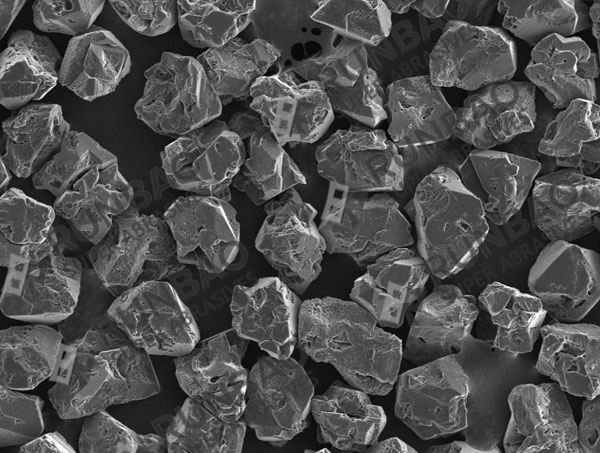

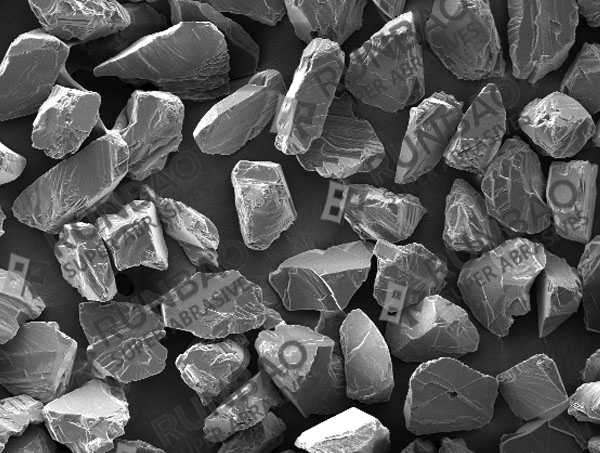

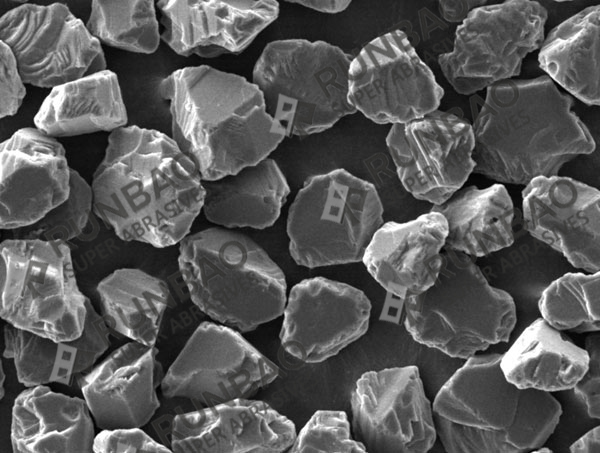

Angular shape, sharp cutting edges, owns electric conduction, high thermal resistance and toughness, it is ideal for high speed grinding and heavy cutting force application.

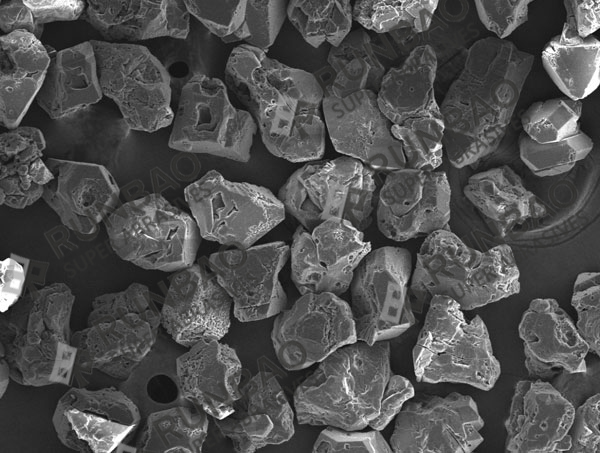

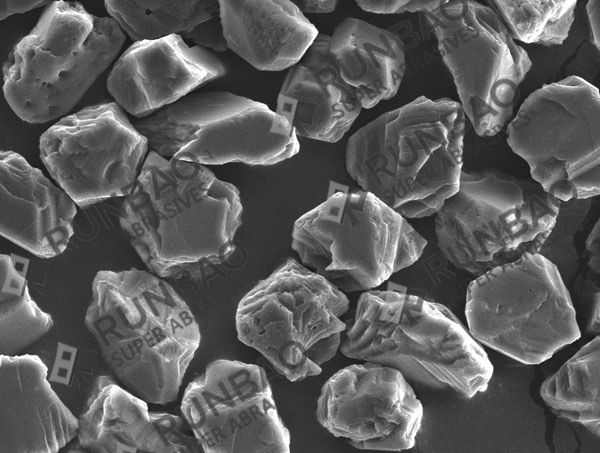

Irregular shape, friability, self-sharpen ability, higher cost performance, which is ideal for cost consideration.

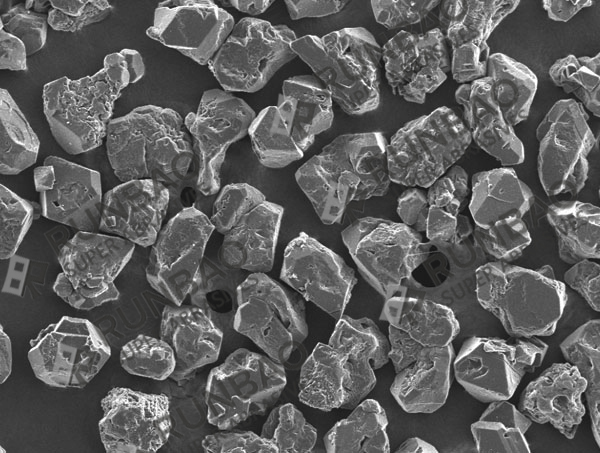

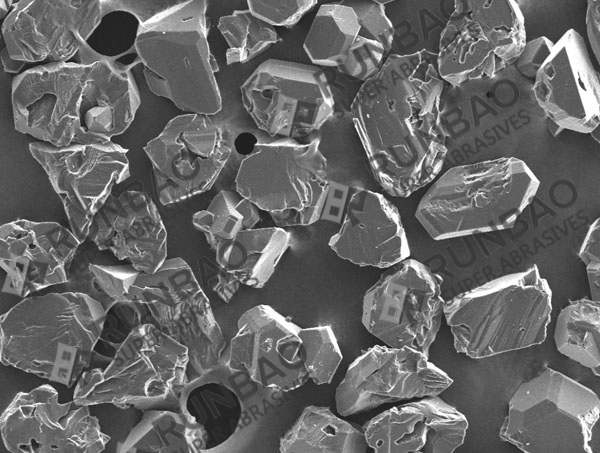

Irregular shape, friability, lots of sharp cutting edges, few inner impurity, lowest magnetic, perfect self-sharpen which balance the grinding performance and tool oI life. it is ideal for very hard tungsten carbide grinding.

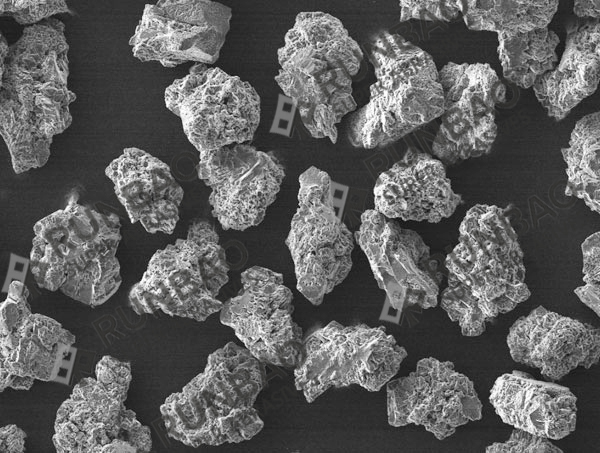

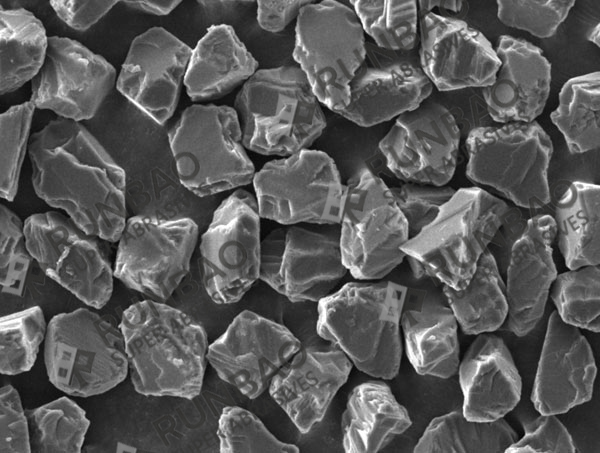

Very friable, micron-grade cutting edges which bring premium surface finishing, rough crystal surface which bring best retention with the bond, micron-fracture mode,excellent self-sharpen ability brings high free cutting rate and cool cutting.

yellow color, semi-blocky shape, sharp cutting edges higher purity, all its characteristic balance the wheel life and cutting efficiency. It is ideal for low cutting force application.

Yellow-green, massive, high purity, low magnetism and high strength can effectively improve the life of grinding wheel.

It is coming from RBV-FS. It is gray and white color. It's excellent self-sharpen characteristic brings perfect gloss

It is coming from RVD-A Higher toughness. It is light yellow and white color. With a lot sharp polishing edges.